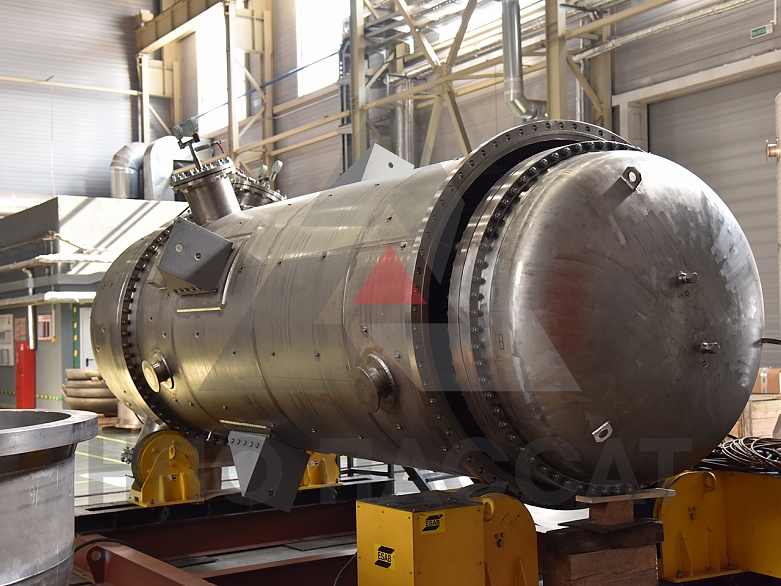

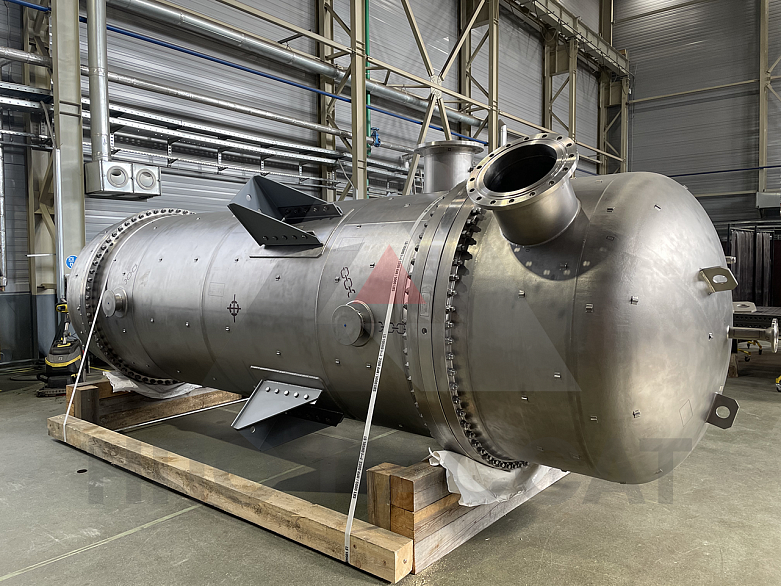

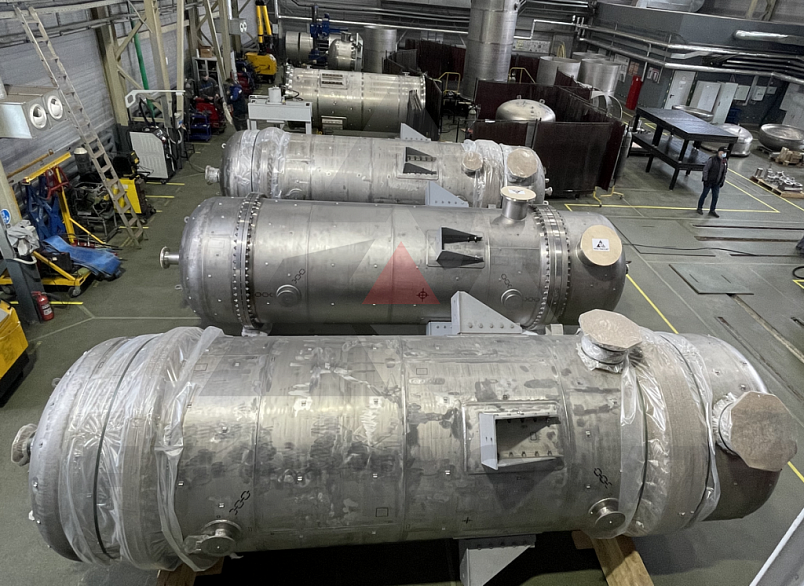

Shell-and-tube heat-exchange apparatuses

Shell-and-tube heat exchangers are the most common among tubular ones. With the relative simplicity of the design, they have a sufficiently large specific heat exchange surface.

They are used as:

- evaporators;

- capacitors;

- heaters;

- refrigerators.

In shell–and-tube heat exchangers, one of the heat carriers moves through the tube space, the other - through the inter-tube space.

It is necessary to direct the coolant into the pipe space:

- to a greater extent polluting the heat exchange surface;

- having a high corrosion resistance;

- having a very high (low) temperature;

- having a lower heat transfer coefficient (with the equivalence of the indicators in the previous paragraphs).

Execution of shell-and-tube heat exchangers:

- with fixed fixing of pipes in pipe grids;

- with lens compensators on the casing;

- with U-shaped pipes;

- floating head.

The choice of execution of heat exchangers depends on:

- the values of the average temperature difference of heat carriers;

- their operating temperatures and pressures;

- materials from which pipes, pipe grilles, casing are made.

Heat exchangers with fixed mounting of pipes in pipe grids and lens compensator:

- single–pass through the pipe space – vertical evaporators multi-pass through the pipe space - vertical and horizontal condensers;

- single- and multi–pass through the pipe space - vertical and horizontal heaters and refrigerators.

Heat exchangers with U-shaped pipes and floating head:

- multi-pass through the pipe space - used as evaporators, condensers, refrigerators and heaters.

The common advantage of heat exchangers with U–shaped pipes and with a floating head is the availability of their inter-tube space for cleaning. In multi-pass shell-and-tube heat exchangers, due to the partitioning of coolant flows at lower costs compared to single-pass ones, it is possible to achieve intensive movement, turbulence and, as a consequence, an increase in heat transfer and heat transfer coefficients.

Multi-pass heat exchangers can be both in the tube and in the inter-tube spaces, and in both spaces at the same time. The pipe space is partitioned by installing partitions in the distribution chambers, the inter–pipe space is partitioned by installing transverse partitions in it, usually segmented.

The proposed heat exchangers are made of various metals and alloys, including titanium, high-alloy stainless steels, the use of which is due to certain characteristics of working media (pressure, temperature, corrosion resistance, etc.) allowing for high thermal conductivity to provide sufficient mechanical, corrosion and thermal resistance of the structure.

Guarantees of investment success of our clients:

- 30 years of work of the Passat holding in the field of industrial engineering, construction and manufacture of equipment;

- 14 years on the market of processing equipment for the potash industry – proven technological solutions;

- A full cycle of equipment production including design, design calculations, R&D, technology automation, the full range of necessary engineering competencies, installation and commissioning;

- Own chemical and technological service for the development of technological solutions and the output of equipment to technological parameters;

- Service standard 24/7/365.

Are you interested in this product?

To request a questionnaire